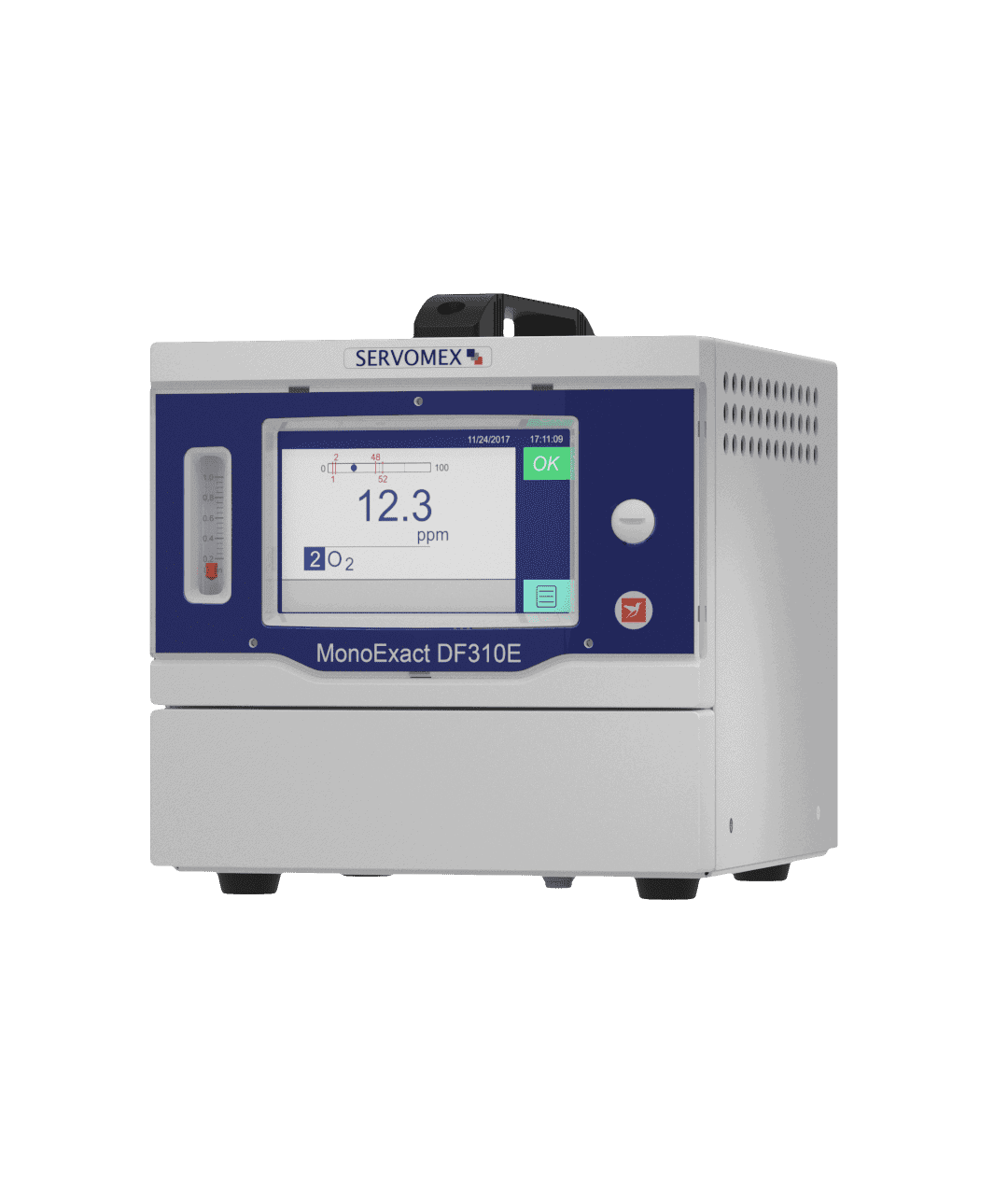

Next-generation Coulometric analysis for a range of industrial applications

Using a new and improved digital touchscreen with icon-driven guider user interface (GUI) for easier operation, the MonoExact DF150E combines the reliability of Servomex’s tried and tested Coulometric oxygen sensor in a more user-friendly package.

Built around the latest innovations in software and hardware, including an updated Coulometric digital oxygen sensor, the MonoExact DF150E brings users new operational and maintenance benefits that improve user control and reduce cost of ownership.